Hello,

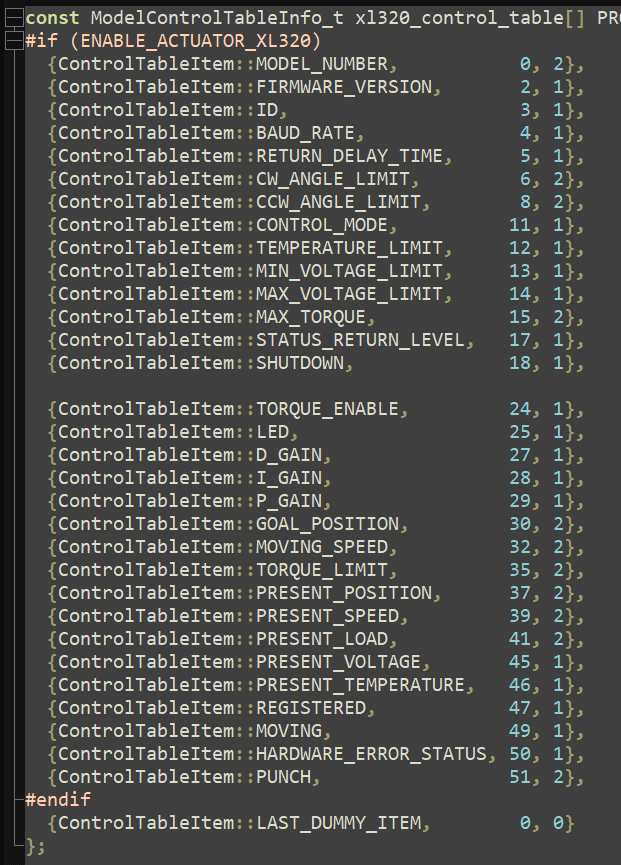

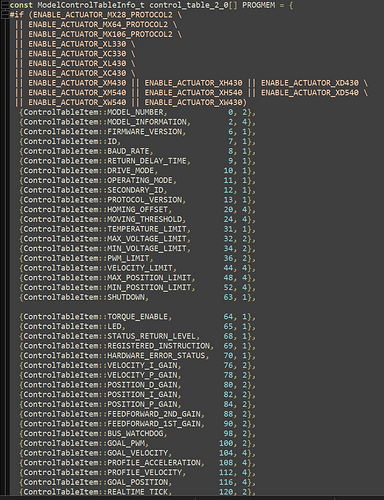

I’m now moving these motors (thanks here - OpenCM9.04 and XL-320 motors not working - Hardware Support - ROBOTIS). But I have been unable to update PID gain values using the “writeControlTableItem” function. I’ve tried to set new values and read them back, but it returns 0 for all the PID values (according to the emanual, the default value for POSITION_P_GAIN is 32, but it returns 0 there as well). Anything I’m missing? I’ll post details and code below.

Thanks!

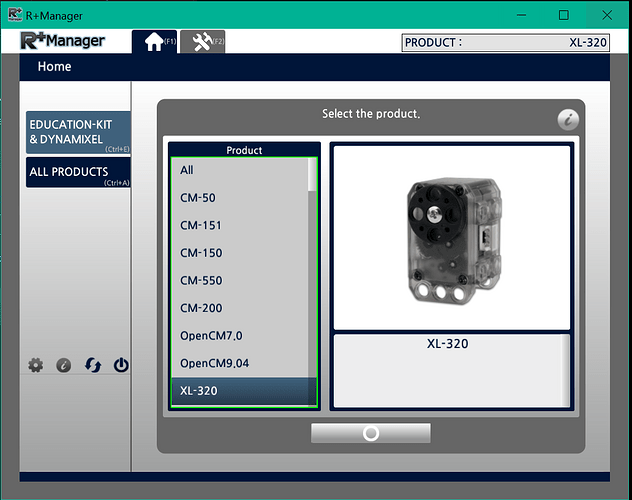

As before, I’m using:

- 2x XL-320 motors

- OpenCM9.04 board, connected to PC via USB

- Arduino IDE v1.8.13

- OpenCM9.04 boards package v1.5.1

- Dynamixel2Arduino library v0.5.1

- no external power supply EDIT 7.4V supplied via bench power supply

Code I’ve been working from:

#include <Dynamixel2Arduino.h>

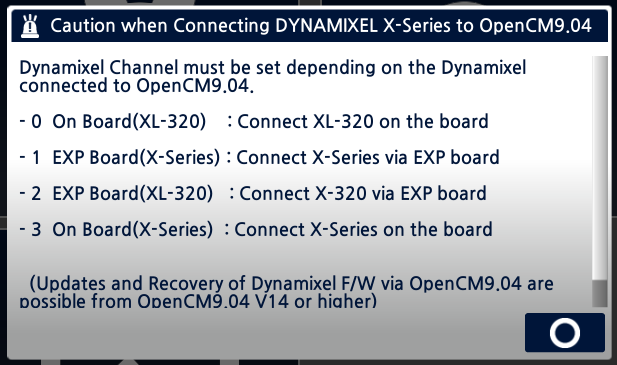

#define DXL_SERIAL Serial1 //OpenCM9.04 EXP Board's DXL port Serial. (Serial1 for the DXL port on the OpenCM 9.04 board)

const uint8_t DXL_DIR_PIN = 28; //OpenCM9.04 EXP Board's DIR PIN. (28 for the DXL port on the OpenCM 9.04 board)

const float DXL_PROTOCOL_VERSION = 2.0;

#define MAX_BAUD 5

const int32_t buad[MAX_BAUD] = {57600, 115200, 1000000, 2000000, 3000000};

#define X_ID 1

#define Y_ID 2

// motors appear to have the center NEAR 512 units but not exactly

#define X_CENTER 520

#define Y_CENTER 526

const float UNITS_PER_DEG = 1024.0/280.0;

// set physical parameters

const float X_ARM_L = 11.0; // mm

const float Y_ARM_L = 16.0; // mm

const float X_MAX = 7.0; // mm

const float X_MIN = -7.0; // mm

const float Y_MAX = 12.0; // mm

const float Y_MIN = -12.0; // mm

const float XY_STEP_SIZE = 2.0 ; // mm

float xTarget = 0.0; // mm, range

float yTarget = 0.0; // mm, range

float xCommand = X_CENTER; // dynamixel step

float yCommand = Y_CENTER; // dynamixel step

Dynamixel2Arduino dxl(DXL_SERIAL, DXL_DIR_PIN);

//This namespace is required to use Control table item names

using namespace ControlTableItem;

void setup() {

// put your setup code here, to run once:

int8_t index = 0;

int8_t found_dynamixel = 0;

// Use UART port of DYNAMIXEL Shield to debug.

Serial.begin(115200); //set debugging port baudrate to 115200bps

while(!Serial); //Wait until the serial port is opened

// // scan for connected motors

// // this can be removed when code is more complete

// for(int8_t protocol = 1; protocol < 3; protocol++) {

// // Set Port Protocol Version. This has to match with DYNAMIXEL protocol version.

// dxl.setPortProtocolVersion((float)protocol);

// Serial.print("SCAN PROTOCOL ");

// Serial.println(protocol);

//

// for(index = 0; index < MAX_BAUD; index++) {

// // Set Port baudrate.

// Serial.print("SCAN BAUDRATE ");

// Serial.println(buad[index]);

// dxl.begin(buad[index]);

// for(int id = 0; id < DXL_BROADCAST_ID; id++) {

// //iterate until all ID in each buadrate is scanned.

// if(dxl.ping(id)) {

// Serial.print("ID : ");

// Serial.print(id);

// Serial.print(", Model Number: ");

// Serial.println(dxl.getModelNumber(id));

// found_dynamixel++;

// }

// }

// }

// } // end scan routine

// Set Port baudrate to 1Mbps. This has to match with DYNAMIXEL baudrate.

dxl.begin(1000000);

// Set Port Protocol Version. This has to match with DYNAMIXEL protocol version.

dxl.setPortProtocolVersion(DXL_PROTOCOL_VERSION);

// Turn off torque when configuring items in EEPROM area

// using position mode for now

dxl.torqueOff(X_ID);

dxl.torqueOff(Y_ID);

dxl.setOperatingMode(X_ID, OP_POSITION);

dxl.setOperatingMode(Y_ID, OP_POSITION);

dxl.torqueOn(X_ID);

dxl.torqueOn(Y_ID);

// Limit the maximum velocity in Position Control Mode. Use 0 for Max speed

dxl.writeControlTableItem(PROFILE_VELOCITY, X_ID, 0);

dxl.writeControlTableItem(PROFILE_VELOCITY, Y_ID, 0);

// mess with PID values

// 27 1 D Gain Derivative Gain RW 0 0 254

// 28 1 I Gain Integral Gain RW 0 0 254

// 29 1 P Gain Proportional Gain RW 32 0 254

dxl.writeControlTableItem(POSITION_P_GAIN, X_ID, 32); delay(500);

dxl.writeControlTableItem(POSITION_I_GAIN, X_ID, 1); delay(500);

dxl.writeControlTableItem(POSITION_D_GAIN, X_ID, 1); delay(500);

// check PID values

Serial.print("XP "); Serial.println(dxl.readControlTableItem(POSITION_P_GAIN, X_ID)); delay(500);

Serial.print("XI "); Serial.println(dxl.readControlTableItem(POSITION_I_GAIN, X_ID)); delay(500);

Serial.print("XD "); Serial.println(dxl.readControlTableItem(POSITION_D_GAIN, X_ID)); delay(500);

Serial.print("YP "); Serial.println(dxl.readControlTableItem(POSITION_P_GAIN, Y_ID)); delay(500);

Serial.print("YI "); Serial.println(dxl.readControlTableItem(POSITION_I_GAIN, Y_ID)); delay(500);

Serial.print("YD "); Serial.println(dxl.readControlTableItem(POSITION_D_GAIN, Y_ID)); delay(500);

Serial.print("X_TORQUE_LIMIT "); Serial.println(dxl.readControlTableItem(TORQUE_LIMIT, X_ID)); delay(500);

Serial.print("Y_TORQUE_LIMIT "); Serial.println(dxl.readControlTableItem(TORQUE_LIMIT, Y_ID)); delay(500);

Serial.print("X_CURRENT_LIMIT "); Serial.println(dxl.readControlTableItem(CURRENT_LIMIT, X_ID)); delay(500);

Serial.print("Y_CURRENT_LIMIT "); Serial.println(dxl.readControlTableItem(CURRENT_LIMIT, Y_ID)); delay(500);

// I think it might need a moment to set the torque on, or something

delay(50);

// move both motors to center positions

dxl.setGoalPosition(X_ID,X_CENTER);

delay(1000); // time to reach position

dxl.setGoalPosition(Y_ID,Y_CENTER);

delay(1000); // time to reach position

}

void loop() {

// print current position

// Serial.print("X pos: "); Serial.print(dxl.getPresentPosition(X_ID)); Serial.print("\t");

// Serial.print("Y pos: "); Serial.print(dxl.getPresentPosition(Y_ID)); Serial.print("\t");

// Serial.print("\n");

// dxl.setGoalPosition(X_ID,X_CENTER + UNITS_PER_DEG*45.0);

// delay(1000);

// dxl.setGoalPosition(X_ID,X_CENTER - UNITS_PER_DEG*45.0);

// delay(1000);

// dxl.setGoalPosition(Y_ID,Y_CENTER + UNITS_PER_DEG*45.0);

// delay(1000);

// dxl.setGoalPosition(Y_ID,Y_CENTER - UNITS_PER_DEG*45.0);

// delay(1000);

// see if user input anything in serial monitor

if (Serial.available() > 0) {

char userInput = Serial.read();

if (userInput == 'a') {

// nudge left (+x)

xTarget += XY_STEP_SIZE;

} else if (userInput == 'd') {

// nudge right (-x)

xTarget -= XY_STEP_SIZE;

} else if (userInput == 'w') {

// nudge forward (+y)

yTarget += XY_STEP_SIZE;

} else if (userInput == 's') {

// nudge backward (-y)

yTarget -= XY_STEP_SIZE;

} else {

Serial.println("Only accepting 'wasd' keyboard input.");

}

while(Serial.available()){Serial.read();} // make sure the buffer is empty

}

// check that values are acceptable

if (xTarget > X_MAX) { xTarget = X_MAX; Serial.println("X_MAX limit."); }

if (xTarget < X_MIN) { xTarget = X_MIN; Serial.println("X_MIN limit."); }

if (yTarget > Y_MAX) { yTarget = Y_MAX; Serial.println("Y_MAX limit."); }

if (yTarget < Y_MIN) { yTarget = Y_MIN; Serial.println("Y_MIN limit."); }

// convert xTarget and yTarget to xCommand (dynamixel unit) and yCommand

xCommand = round( degrees(asin(xTarget/X_ARM_L)) * UNITS_PER_DEG + X_CENTER );

yCommand = round( degrees(asin(yTarget/Y_ARM_L)) * UNITS_PER_DEG + Y_CENTER );

// move

dxl.setGoalPosition(X_ID,xCommand);

delay(100);

dxl.setGoalPosition(Y_ID,yCommand);

delay(100);

Serial.print("Targets (x,y): "); Serial.print(xTarget); Serial.print(", "); Serial.print(yTarget); Serial.print("\t");

Serial.print("Command (x,y): "); Serial.print(xCommand); Serial.print(", "); Serial.print(yCommand); Serial.print("\t");

Serial.print("Current (x,y): "); Serial.print(dxl.getPresentPosition(X_ID)); Serial.print(", "); Serial.println(dxl.getPresentPosition(Y_ID));

// delay(100);

}And a sample of the output in the following post!