Hello, I have been using xm430-w350 motors and I really enjoy using them!

I’d like to ask one question regarding dynamixel SDK.

So to actuate the motors in python, I have been using the following scripts:

def set_command_position(id_position_list):

if connected:

ADDR_PRO_GOAL_POSITION = 116 # Control table address

LEN_PRO_GOAL_POSITION = 4 # Data Byte Length: Note the unit is byte = 8 bits = 2 bits HEX

# Wait until the USB port is released =========================================================================

ttyUSB_data = glob.read_one_data(glob.mem_ttyUSB_data, 'portOccupied')

while ttyUSB_data[0]:

ttyUSB_data = glob.read_one_data(glob.mem_ttyUSB_data, 'portOccupied')

# Occupy the USB port =========================================================================================

data_usb_occupied = {}

data_usb_occupied['portOccupied'] = np.array([1.0])

glob.mem_ttyUSB_data.set(data_usb_occupied)

lock.acquire()

#print("Lock acquired for send command ----------------------------------------------")

# compose sync_write package

groupSyncWrite = GroupSyncWrite(portHandler, packetHandler,

ADDR_PRO_GOAL_POSITION, LEN_PRO_GOAL_POSITION)

num_of_motors = len(id_position_list)

for iter in range(num_of_motors):

DXL_ID = id_position_list[iter][0]

dxl_goal_position = rad2tick(id_position_list[iter][1])

# Allocate goal position value into byte array

# A word = 4 digits HEX number = 16 bits binary number = 0 - 65535, thus 65536 has loword=0 and hiword=1

# LOBYTE and HIBYTE separates low 4 digit HEX into 2 low + 2 high digits and express in DEX

# e.g. 2047 has LOBYTE=255 and HIBYTE=7, since 15 + 15*16 = 255, 255 + 7*16^2 = 2047

param_goal_position = [DXL_LOBYTE(DXL_LOWORD(dxl_goal_position)),

DXL_HIBYTE(DXL_LOWORD(dxl_goal_position)),

DXL_LOBYTE(DXL_HIWORD(dxl_goal_position)),

DXL_HIBYTE(DXL_HIWORD(dxl_goal_position))]

# Add Dynamixel goal position values to the Syncwrite parameter storage

dxl_addparam_result = groupSyncWrite.addParam(DXL_ID, param_goal_position)

if not dxl_addparam_result:

print("[ID:%03d] groupSyncWrite addparam failed" % DXL_ID)

return False

# Syncwrite goal position

dxl_comm_result = groupSyncWrite.txPacket()

if dxl_comm_result != COMM_SUCCESS:

print("%s" % packetHandler.getTxRxResult(dxl_comm_result))

return False

# Clear syncwrite parameter storage

groupSyncWrite.clearParam()

# Release the USB port =========================================================================================

data_usb_occupied = {}

data_usb_occupied['portOccupied'] = np.array([0.0])

glob.mem_ttyUSB_data.set(data_usb_occupied)

lock.release()

#print("Lock released for send command ----------------------------------------------")

return True

else:

return False

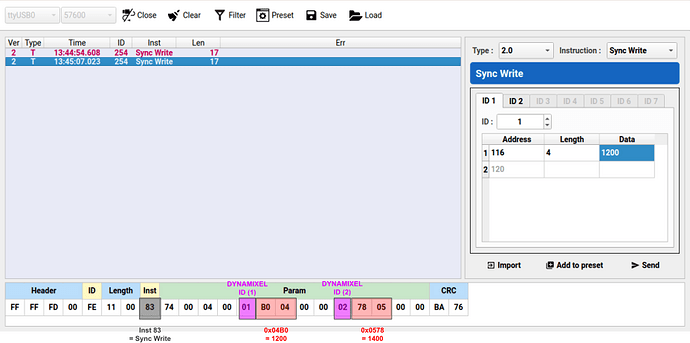

The problem I face so far is that the motors generate different angles although “param_goal_position” in the above code is identical between two different motions.

One thing I noticed was that the issue does not exist anymore if I set the range of the joint angles from 0 to 4096. It seems that when we command the joint angle which is outside the feasible range, sometimes I get the totally random motion even with the same “param_goal_position”.

-

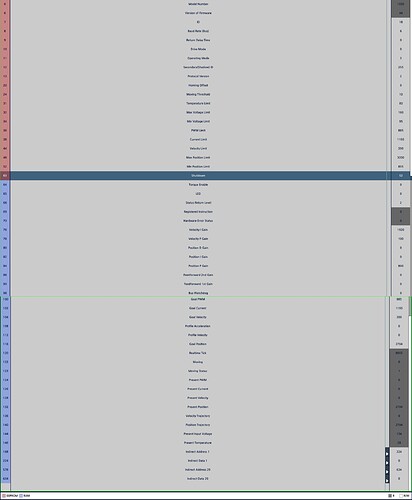

This is what we use as settings in R+ manager:

-

We use 14.1 V as an input voltage to the OpenCM 485 Expansion board.

-

We use Python 3.

I look forward to hearing from you!

Best regards,